Questions About the Scan Software SilverFast

For all current scanner models, SilverFast is avaliable in our Filmscanner-Shop. SilverFast is the worldwide leading software for film scanners and flatbed scanners. Almost every scanner, even those which have disappeared from the market a long time ago, can be operated with SilverFast. On this page, we have collected numerous questions and answers related to the scan-software SilverFast of the German company LaserSoft Imaging. Please consider that in our Forum there is also a special area for the scan software SilverFast. In the follwing text we first present an overview of all topics treated in our page:

Information about SilverFast Version 9

Information about SilverFast version 8

SilverFast Versions, Licences, Updates

Image Quality with SilverFast

IT-8 Colour Calibration

IT-8 calibration with advanced IT-8 Targets

Dust - and Scratches Corrector SRD, iSRD, ICE

Printer Profiling with SilverFast Profiler at Version 6.6

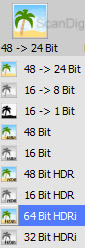

Questions about Silverfast HDR (High Dynamic Range)

Questions about SilverFast DCPro

Other Topics About SilverFast

Information about SilverFast version 9

By the end of 2020 Lasersoft Imaging brought the version 9 of SilverFast to the market. Thus the "old" version 8 had a life time of about 10 years, which is remarkable in the software area.

What is new within the SilverFast version 9?

What is new in the version 9? The essential change compared to the version 8 is the mode of delivery: While the version 8 was delivered mainly on DVD, the version 9 is only delivered digitally. You only get an activation key which consists of 8 characters. With this activation key you can create a My-SilverFast-Account and activate and download the appropriate software. Everything goes completely digital, there is no DVD and no printed manual any more.

In terms of functionality not much has changed in the version 9 compared to the version 8, at least if you compare the version 9 with the last version 8.8. The graphical user interface appears in a new modern outfit. There was an essential change not before the version 9.1: The Archive-Suite was extended by the Express-Scan function. The Express scan function accelerates a scan procedure always when you digitize several similar films or photos. Fir instance, if you scan 3 film strips with an Epson Perfection V850 Pro, not image by image will be processed, but the CCD sensor runs across the complete glass surface of the scanner in one turn and so detects all films at a time. The same holds if you put several paper photos, for example, on an Epson Expression 13000XL; here image by image isn't scanned either, but in one scan procedure all photos are captured at a time. Of course at the end several image files are created, one for each original. This express scan function accelerates scanning upt to a factor of 6 according to our measurements.

How much does an upgrade to version 9 cost?

Usually upgrades are cheaper than a new version, except the new version is part of a scanner bundle. There are upgrades available from the old version 8, but also from the very old version 6. Of course the upgrades from version 6 to 9 are more expensive than upgrades from version 8 to 9.

If you are interested in an upgrade, please, just send us an e-mail with your existing SilverFast version number, the corresponding serial number and scanner model for which the software is to be used and may be used to. Then you will get an individual and non-binding offer.

Is it worh upgrading to version 9?

As described above the version 9 of SilverFast does not have essential differencies to version 8 in terms of functionality and features. An essential difference, however, is the compatibility with modern operating systems: While the version 8 (and older versions, too), do not run with some actual operating systems any more, the version 9 runs on actual Windows- and Mac- operating systems. And the verison 9 is permanently adapted if new variants of operating systems appear.

While the version 8 and older versions are not maintained and developed any more, for the version 9 there are again and again upates with small changes, bug fixes or new functions. Just because of this it is worth upgrading to the actual version.

Information about SilverFast version 8

In August 2011 Lasersoft Imaging launched the new SilverFast version 8 as successor of the version 6.6 (version 7 has been omitted). The switch to the new version was made not abruptly but in several stages. The software has not only obtained an optical facelift and now offers a modern, practical design of the work surface, but there were also integrated many improvements and new features. Below there is a summary of new features and changes in SilverFast 8 compared to the previous version, as well as information about the availability of different scanner models.

Which features are new in the version 8?

SilverFast 8 offers several new features compared to the previous version 6.6:

Compared to older SilverFast versions a new preview concept enables enhanced monitoring of the effects of image settings. Even complex corrections like the hardware based dust and scratch removal can already be assessed in the preview scan and be matched exactly. In this connection a 100% zoom helps to assess and to optimize the settings and adjustments.

The new GUI (Graphical User Interface), has been revised for the version 8 and is now up to date. Compared to the previous version, the user interface has become clearer and clearer, so that a novice quickly copes with it as in the previous version. All controls can be placed by mouse per drag & drop to anywhere on the screen, so you can spend your working environment as you like yourself.

SilverFast 8 is now fully capable of multitasking. Unlike the older versions, it is now possible with version 8, to perform other activities on the same computer in addition to scanning. Up to version 6 the computer was fully used to capacity during the scan, so it could be hardly used for other tasks such as image editing. Even within the SilverFast scanning software is the new multi-tasking ability of advantage: Thus, the second frame can be created and the settings be made, while the scanner is scanning the first frame.

The new advanced selective color correction of SilverFast 8 allows corrections in several layers. So you can correct similar colors in different areas of the image using masks independently. It is possible to define up to four layers. Elaborate selective color corrections no longer need to be carried out later using an image editing program.

The new WorkflowPilot as essential core element of SilverFast 8 replaces the old Scan Pilot, and guides the user step by step through each of the required workflow. The workflow pilot assists in form of explanatory text and available QuickTime movies. The workflow pilot prevents errors in the operation and provides especially beginners and casual scanner users considerable assistance. Advanced users of course can do without the workflow pilot and implement a standalone workflow.

Which version variants are there in version 8?

SilverFast Version 6 was available in 4 variants SE, SE Plus, Ai and Ai Studio. In addition there was also Archive Suite respectively Archive Suite SE. All these versions are also available in version 8 except Ai-standard version. Below we list the main features of the available versions:

SilverFast SE 8: This is the entry-level version of LaserSoft Imagings scan software. Despite reduced features within this version you can already achieve excellent image results. The SE version already includes the WorkflowPilot that takes you step by step to the optimized result; the preview concept for immediate inspection of each image optimization; the automatic image for fast, compelling results; iSRD for a thorough infrared dust and scratch removal and selective color correction for easy color adjustments. SilverFast SE Plus 8: This version is based on the SE version and provides extended functionality for advanced users and to achieve even better image results. In addition to the features of the SE version the SE plus version also includes the multiple exposure, called multi-exposure in order to increase the dynamic range and to obtain maximum details. In addition, the SE Plus version has the Auto Frame Alignment in combination with the Automatic Frame Detection. The Auto Frame Detection with automatically alignment is very helpful especially for flatbed scanners. The well known AACO (Auto Adaptive Contrast Optimization) from the version 6 is also included in the SE Plus 8. SilverFast Ai Studio 8: This version is made for professional photographers and advanced users, and is the professional version. It is fully functional and has all the features, even for the highest demands. In addition to the features of the SE Plus version there is the option of Auto IT8 Calibration in the Ai Studio version. With an optionally available target you can calibrate the scanner within 2 minutes in order to save color errors of the scanner in a correction profile. With the JobManager in SilverFast Ai Studio there is also a convenient way to batch processing is included. Furthermore the Kodachrome feature, the 16Bit histogram, the expert modes, self-created and editable NegaFix profiles, working with masks and layers in the dust and scratch removal and the selective color correction are helping to get professional results and optimized workflows. Detailed information about the benefits of Ai Studio version can also be found in the FAQ item Which advantage does the SilverFast Ai Studio version offer?.

In addition to these 3 basic versions, there is the Archive Suite or the Archive Suite SE. These are packages of the Ai Studio version or the SE Plus version with the current HDR Studio version, so that you can create raw scans with Ai Studio or SE Plus which can be processed at a later time with HDR Studio.

For which scanner models is the version 8 available?

For the main scanner models, SilverFast 8 is available since the publication date. Other models will be added continuously. Which scanners SilverFast 8 is currently available for can be found in the List of supported scanners.

For some scanners, especially ones long disappeared from the market, there is no version 8 available because there are no drivers available for current operating systems. For such scanners the previous version 6 remains as an alternative. An overview of available versions can be found in our SilverFast category in our online shop.

For many scanners, there is no DVD version of version 8 available, just download versions. If you buy a download version from us, you will receive a license key and a download link by email.

What does it cost to upgrade to version 8?

If you have a previous version of SilverFast, this can be easily upgraded to the latest version 8 (if there is a version for your scanner model available). LaserSoft Imaging makes special offers to its customers. Depending on your version of SilverFast discounts of 20%, 30% or even 50% are granted.

If you are interested in a paid upgrade, please, just send us an e-mail with your existing SilverFast version number, the corresponding serial number and scanner model for which the software is to be used and may be used to. Then you will get an individual and non-binding offer.

SilverFast Version, Licences, Updates

Which advantage offers SilverFast in comparison to current scan-softwares?

SilverFast is a professional scan software which price differs depending of the type of film scanner. Is the acquisition of a professional scan software worthwhile and are there advantages? Previously, it should be said that in case of a flmscanner, the software is not only a tool to handle the device but the scan software contains some essential algorithms for the image processing that produce a digital image from the raw data provided by the scanner.

SilverFast has, without doubt, the best algorithms for the image processing that bring definitely more out of the raw data of the scanner than some of the cheap scan-softwares. There are film scanners which have a range of density of 2,5 with the in-house software, but with which SilverFast exceeds a range of density of 3. The resulting differences in the image quality can be very significant in the lights or shadow areas and play a decisive role if one evaluates a type of scanner as a high quality or a standard device. With the SilverFast Ai Studio 8 it is also possible to use layers and masks for iSRD and the selective color correction.

With the multi exposer function of SilverFast (contained in Ai Studio and SE Plus), the dynamic range can even be significantly increased. Since with this function ot only a typical multiple scan but also a multiple exposure scan is done. A template is multiple scanned with different adjustments of exposure and the results are interpolated. By this way, SilverFast does not only provide an effective noise supression but also clearly better colors due to the increased dynamic range.

Silverfast is generally a very extensive and multifunctional scan software. There is practically no mode of configuration that is not available in SilverFast; from the simple brightness regulator up to a complex curve tool, everything what is needed for the optimal configuration of the scanner is available. Moreover, SilverFast offers a lot of professional functions for saving the personal special configurations for certain proceedings or for the configuration of personal profiles for determined types of films or recordings. Thus, SilverFast offers an abundance of professional configurations and proceedings for the image editing, that other scan programes cannot even roughly offer.

But the main advantage of SilverFast Ai Studio is the IT-8 Calibration. Using an IT-8 calibration target (optionally available in our shop), the scanner is measured and an ICC profile is generated. This calibration has a very positive effect on the image quality and one works in a color management process and does not depend on the casual condition of the filmscanner for slides. The IT-8 calibration is not effective if you are scanning negatives, for scanning negatives SilverFast offers the so-called negafix-dialogue in which one you can exactly configurate your used type and sort of film. With the saved color profile you recive significantly better results of negatives than if you use a standard color profile. You will find some further information about the advantage of the IT-8 calibration in our chapter IT-8 Calibration also there are more detailed informations on our website about Scanner Calibration.

SilverFast SE Plus8 and Ai Studio 8 includes the Auto-Frame Function. What does this mean? Normally, a prescan is made before the final scan and the exact scan area is choosen manually so that the image is scanned without an additional black frame. SilverFast accomplishes this with one mouse click. The right scanning area is automatically recognized after the prescan so that the manual adjustment of the image area is not necassary any more. This automatic frame detection saves a lot of work, and in case of flat bed scanners which can scan several images at once. This function is even more useful, as it automatically recognizes several single images which were positioned on the scanning surface.

Finally, an advantage of Silverfast should be mentioned: those who get deeply introduced into the use of SilverFast can easily change the type of scanner, as the handling is the same. If you once learned to handle SilverFast, the acquired knowledge of using filmscanners can be also transferred to flat bed scanners. This saves a lot of valuable time of introduction when changing the scanner model or when purchasing an additional scanner.

Conclusion: the purchase of SilverFast for a filmscanner is in any case worthwhile, specially for those users who make a point of best image quality and a wide range of features. Sometimes the combination of cheap filmscanners and SilverFast is better than an expensive filmscanner without SilverFast. I also would like to mention that SilverFast can be simply tested for free before you purchase it by downloading the demo version from the SilverFast website.

Which advantage does the SilverFast Ai Studio version offer in comparison to the SE Version?

SilverFast Ai Studio is the professional version of SilverFast. The main advantage is the IT-8 Auto-Calibration. With an optional target you are able to calibrate your Scanner. You can find more informations about the scanner calibration and the targets at Which advantage does the IT-8 colour calibration offer?.

Since the version 6.5, SilverFast SE Plus and SilverFast Ai Studio contains Multi Exposure. Thereby, a slide and/or a negative is multiple scanned with different configurations of exposure. Then the software computes from all these differently exposured images an optimal image that stands out from a normal scan by a higher dynamic range. Every photographer knows this effect: By taking a photo of the same object repeatedely with different combinations of time/apertures, one exposure has more details in the shadows and the other more details in the lights. By combining these two images, one gets a highly dynamic-ranged detailed photography. The multi exposure function does also reduce the image noise of the scanner. More information and examples about the multiple exposure are available in the chapter Multi Exposure.

A further feature of the Studio- and SE Plus-Version is the AACO Auto-Adaptive Contrast Optimization. This function works fully automatically, optimizes the dark image areas with a low contrast by keeping sufficient drawing in the bright areas. The studio version can also save images in JPEG2000 format and save ITPC comments in the single image files.

More highlights of the studio version are available in the image processing: At many features there is an expert-mode available. If you activate this you have a lot of extra parameters for the fine adjustment of the image optimization. There is also a 16-Bit Histogram. With this you can make your settings for the black- and whitepoint and midtones. Depending on your selection you can view combined or separated color channels. Also the choice between RGB and CMY mode is possible with the 16 Bit Histogram. Masks and layers can be used for iSRD and the selective color correction with SilverFast Ai Studio. This is especially for Kodachrome and black-and-white pictures. Editing your own NegaFix profiles will cause much better results for negatives. And the Jobmanager is a batch tool for making scanning much more comfortable.

And finally, a feature of the Studio and SE Plus version should be mentioned that would not be priorily searched in a scan software: with the function PrinTao of SilverFast one gets a professional print tool for printing scans and photographies. For example, a typical appliance consists for example in printing some images on a DIN A4 (21x29,7cm) sheet after the scanning or in printing an overview of a 24-film on a sheet. With PrinTao, one issues fast and easily a compilation of the images to be printed and of course, some texts for the labellings can ne added. Certain drafts are then saved as templates, for example in order to print 36 thumbnails of a film on a DIN A4 sheet as an overview; this makes the next printing procedure considerably faster. Of course, SilverFast would not be SilverFast if it would not operate the color management during the printing.

Which advantage does SilverFast HDR offer?

SilverFast HDR is a software for the later processing of raw image files that can be released during the scan with SilverFast Ai Studio and SE Plus. It is about an independent software, thus not an expansion of the SilverFast Scansoftware. Similar as it is the case in the raw files of the digital cameras, all image configurations that are independent from the hardware can be then accomplished afterwards and the image can be optimized according to the personal wishes. Only after a click on the processing button, the finished image file is computed and saved according to the configurations previously done.

Thus, during the scan procedure, one does not have to care yet about the image configurations as the contrast, brightness, chromaticity, sharpness, etc. - all this can be unhurriedly adjusted at a later time without losing in quality. Only the configurations that depend on the hardware as resolution and the ICE dust and scratches remover have to be selected and/or activated already during the scanning procedure.

HDR is the abbreviation for High Dynamic Range: the raw data contain the full dynamic range of the scanner in use, so that the maximum of image information is available for the later processing. Thus, with this procedure, the best possible image results of the scanner in use can be achieved.

The raw scans are perfectly suitable for the archiving, as, depending on the purpose, an optimized image file can be generated. After closing and reopening a raw file, all parametres are kept, so that, for example, the colour adjustments of the last processing are kept and can only adapt the sharpness of the required output size of the image.

The Division of the scanning procedure and the image configuration makes also possible that the scans can be made by a different person of the one who decides about the finished image. Once the required output resolution is adjusted, the person at the scanner only has to feed it with templates - the rest is done later. If the templates are only available for a limited time period, they can be quickly digitalized as HDR-raw scans. The time consuming image configuration can then be done unhurriedly after the return of the templates.

SilverFast HDR is an independent software that runs independently of SilverFast Ai Studio or SE Plus and independently of a scanner.If, for example, raw scans are generated with SilverFast Ai at one working station, these files can be transferred to another working station and process them with SilverFast HDR. Within the framework of our scan-service we also offer to generate the scans in HDR format. The further processing can then take place with SilverFast HDR without a scanner. By this way, all configurations in the scan software can be done by oneself without having a scanner.

You will find some further detailed information and a detailed test report about SilverFast HDR in our SilverFast HDR Website.

Which advantage does the SilverFast Archive-Suite offer?

The SilverFast ArchivSuite is a bundle of two SilverFast-products, SilverFast Ai Studio and SilverFast HDR Studio. With SilverFast Ai Studio, raw scans can be generated that are later processed in SilverFast HDR Studio and further processed to definite image files. For further information of both studio versions, see above. There is also the opportunity to purchase the SilverFast SE Archive Suite. This bundle contains SilverFast SE Plus and SilverFast HDR Studio.

For which scanner models is SilverFast available?

SilverFast is available for almost all kinds of scanners that are available on the market and ever were available on the market. There is hardly a scanner for which there is no special version of SilverFast. SilverFast is not only available for the consumer devices and professional filmscanners and/or flat bed scanners but also for industrial scanning machines, for example for the old Heidelberg scanners that are not produced anymore or the linotype scanners, there are still SilverFast versions available.

This is also a decisive advantage of SilverFast: for some of the older scanners that are long ago not produced anymore and which original in-house scan software does not work anymore on the current PC's, a SilverFast-software with updated features is available that can bring "death" device back to live again.

If you need the current SilverFast software for an exotic or an older model of scanner, you are welcome to contact us. We can tell you immediately whether there is a current version of software for your model of scanner and if so, we also inform you about the price.

Why does the price for SilverFast differ from scanner to scanner?

If you browse our SilverFast price list you will see very different prices for one and the same software. The question comes up whether it is about the same software with the same range of features or which differences there are between each of the versions. First, there is to mention that there are different variants of SilverFast, as for example the Ai Studio version, the limited SE-version or the Archive Suite Version, but even among these groups there are considerable differences in the prices.

For every scanner, SilverFast Ai is the same, approximately 90% of the basic functions are identical. But there are some small differences in the range of features that are due to the scanner-hardware. Thus, in the case of a filmscaner with ICE3, SilverFast Ai has, for example, three additional buttons for the ICE dust remover or the GEM Grain Equalization & Management. The software also differs depending on the handling of the scanner: a scanner that makes a batch modus of 5 slides possible enables more additional possibilities of adjustment and selections than a scanner that can only process the slides one by one.

But these minimal differences of the functions from filmscanner to filmscanner do not justify the partly significant differences in the prices between the individual licences of SilverFast. It is much more a question of the marketing strategy with which LaserSoft Imaging does sell its product. Thereby, each of the devices are subdivided in different price categories and for each price category there is a respective price for the software of SilverFast. As rule of thumb, it is applied: the more expensive the scanner, the higher the price of LaserSoft Imaging for the respective software of SilverFast.For the customer, there is no way around it, as the software is always taylored to a special device.

Is the SilverFast-licence applicable to several scanners?

SilverFast is an excellent but not very cheap scan software. Those who are so lucky to to get a SilverFast-licence bundled to the purchase of a scanner will save a lot of money compared to the usual selling prices. SilverFast is a software of always the same appearance but individually adapted to each scanner, that means that a SilverFast-licence is only valid for the scanner it has been purchased with.

For example, those who own SilverFast for the Nikon Super Coolscan 4000 cannot apply this version to the follwing model Nikon Super Coolscan 5000. Those who have either a filmscanner as also a flat bed scanner connected to their PC will need two licences of SilverFast, one for each scanner. Those who already have a licence of SilverFast and want to change the scanner model can do this within a cross-upgrade.

Can two SilverFast-versions be installed simultaneously on one PC?

Those who have two scanners connected to one PC, for example a filmscanner and a flat bed scanner and want to operate them both with SilverFast, will need, as known, two single licences of SilverFast, as the software is attached to one device. But it is possible to install SilverFast twice on the PC and, depending on the scanner in use, activate the respective version. Thus, there is no need to have a separate PC for each scanner.

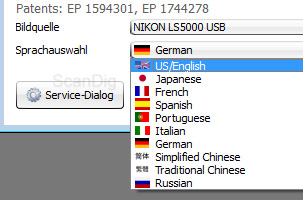

After starting SilverFast the right Scanner can be choosen at the left side of the starting window, by simple click on the bar.

But it is not possible to operate two scanners at the same time, as the interface only permits the data of one device. But if you use SilverFast HDR you are still able to use the Scansoftware SilverFast at the same time.

Where are the SilverFast updates available and how much do they cost?

By purchasing SilverFast one usually gets a current version, thus for example the version 8.0 But one should anyway look for updates immediately after installing SilverFast, as there oftenly are smaller updates with corrected failures in the scan software. The smaller bug fixes are not counted up by the version numbers but by releases, for example from the version 8.0.0r1 to 8.0.0r2.

Updates are available on the website of SilverFast for free. The updates within the releases (for example from 8.0.0r1 to 8.0.0r2) or the 3rd version stage (for example from 8.0 to 8.0.1) are provided by LaserSoft Imaging free of charge. Updates within the subversion are partly free of charge, but partly also with costs. Please contact us if you need further informations.

If you want an update of an older version of SilverFast to a current one, you are welcome to contact us. As dealer and distributor of SilverFast, we can provide you all upgrades quickly and at a reasonable price. The upgrades from SilverFast Ai Studio to SilverFast Archive Suite or from SilverFast SE to Ai Studio are also possible.

Are there SilverFast upgrades from one to another scanner?

If one owns for example a SilverFast licence for an Epson scanner, he cannot use the licence for a Canon or a Nikon scanner, neither for a different model of Epson. (see respective Question). In order to upgrade an existent licence to another scanner, LaserSoft Imaging offers so-called cross upgrades. By this way, it is, for example, possible to upgrade a SilverFast Ai licence of a Canon 9950 to a Nikon 5000. But the saving in case of an upgrade is only small compared to a new purchase.

If you want a cross-upgrade, you are welcome to contact us. As dealer and distributor of Silverfast, we can provide you any upgrade quickly and to a reasonable price.

Is the SilverFast-software delivered with a good user manual?

SilverFast is either delivered with a mini handbook or with a user manual as PDF file. Both variants are rather sparsely, as they do introduce the user in the programe handling but do not introduce the user in the matter of the scanner in a way that is easy to understand. There is a lot of room for improvement for the manufacturer of SilverFast LaserSoft Imaging.

For those who wish a detailed introduction into the SilverFast software that is also easy to understand, I recommend the book SilverFast - Das offizielle Buch of Taz Tally. More about the book can be read in my review (only in German available) of the book.

This textbook is really highly recommendable, either for beginners who first need an introduction into the matter of a scanner, as also for advanced learners who want to get informed about further details of SilverFast, as also for professional users who want to learn more about the numerous expert dialogues of SilverFast.

Unfortunately this text book is written for the version 6 of Silverfast. The main functions of scanning have not changed from version 6 to version 8 or 9, however the graphical user interface. In order to learn how to scan and how to do with the setting possitilities this book is still excellent, however not for learning working with the new GUI. On the other hand, the new graphical user interface is very intuitive and can be operated easily.

As an alternative we recommend the e-book Scanning Workflows with SilverFast 8 from Mark Segal. The book is very comprehensive and written in English. It can be bought at this website.

Is it possible to test SilverFast 8 befor purchasing?

Usually delivered software is always sealed and after you broke this seal you can not return the Software. In this way Software manufacturers protect against misuse or piracy.

Because normally a customer is not willing to buy a software just blindly based on a product description, software manufacturers usually offer trial versions of their software. The trail version of SilverFast is available at the Silverfast manufacturer Lasersoft Imagings website.

At the website of Lasersoft Imaging you can chose the software version of any available scanner, download the trail version and testing it. You can use any SilverFast feature (exluded IT8-Calibration) and there are only little water marks in the scans. With the water marks you can not use the scans but you can test the whole scanning and the operation before you decide to purchase it.

If you are not sure if SilverFast is the right scan software we advise to download the trail version before unsealing your purchased software. You can make the first scans with the SilverFast trail version and if you are satisfied with the results you can unlock the trail version with your serialnumber. You donīt have to reintall the software. If you first use a trail version there is also the advantage that the trail version is always up to date.

Image Quality with SilverFast

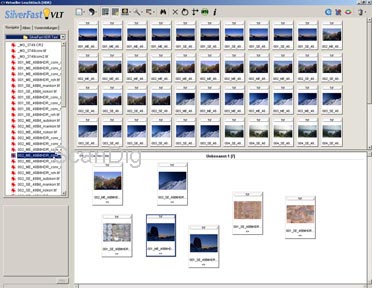

Examples of the increasing image quality by SilverFast

A comparison with the results of the scan software of Reflecta, CyberView, is supposed to show how the scan quality is increased by the use of SilverFast. Thereby, we have employed a very popular slide scanner that is Reflecta DigitDia 5000. CyberView is the scan software that is included in the standard scope of supply of DigitDia, SilverFast is available for an additional payment. In our comparison test we have accomplished the IT-8 colour calibration with SilverFast.

After a click on one of the sample images, an image window opens that switches any three seconds from the scan with CyberView and the scan with SilverFast. By this way, both scan results can be straight and easily compared to each other.

It is noticeable that the image results of SilverFast are of clearly more luscious colours and have more contrast without losing image information in the lights or in the shadows. The scans of SilverFast are much closer to the template than the scans of CyberView.

Moreover, the shadow draw is much more differentiated in the scans of SilverFast: in the dark image areas, the slight nuances are much clearer than with CyberView. In the following sample image, after a click on the thumbnail you can see a 100% cutout of the area marked in red. Here, the image also switches any three seconds between the scan of CyberView- and the one of SilverFast.

In the samples shown here, only the tonal values were adapted in order to generate the GIF animation. Regarding the image optimization compared to Cyberview and other scan software, SilverFast offers significantly more tools that enable the user to make very precise changes of the colour, gradation and the distribution of the tonal value and therewith adapt the image result according to one's ideas.

The quality differences between the standard software CyberView and SilverFast do differ depending on the scanner model. If this test of comparison is made with ten different digit slides, one obtains 10 different scans with CyberView. But thanks to the IT-8 calibration, SilverFast sets the 10 scans on a uniform colour level, so that the scans of SilverFast practically cannot be distinguished. Thus, the more the scanner differs from the ideal colour with the software of CyberView, the more the IT-8 colour calibration corrects and the bigger result the differences in the quality.

The employment of Silverfast as a scan software leads to the fact that in the case of many standard scans, the image processing afterwards can be fully omitted, as the colours are correspondent to the ones of the original. By using the standard software, the image processing afterwards is practically obligatory.

Which kind of quality increase does MultiExposure provide?

SilverFast Ai Studio and SE Plus offers the MultiExposure function. With this feature, an image is scanned several times with different exposures. The resulting images are computed by the software to one single image. By this way, the dynamic range of the scan is increased.

By clicking on one of the sample images, an image window opens with an enlarged presentation, whereby any three seconds it switches between the presentation of the image scanned with and without MultiExposure. For the comparison with/without MultiExposure, we have employed the magazine scanner Reflecta DigitDia 5000 , as it is a very popular device that is purchased oftenly.

As visible, the images scanned with MultiExposure contain more luscious colours and a higher contrast. But thereby, the image information does not get lost. The shadow areas of the scans without MultiExposure appear clearly more dull. Here, the dark image areas are not so drawn as it is the case in the scans with MultiExposure.

But in the lights, there is no increase of the drawing visible that is worth to be mentioned. Thus, in the scan with the Reflecta DigitDia 5000, MultiExposure mainly provides more drawing in the shadows, more luscious colours and a higher contrast. There is to consider that this function can have a different effect in the different scanners - an increase of the dynamic range, no matter if due to a drawing in the shadows or in the lights or in both, but it is always the case. The increases in the quality are specially strong by scanning with a low dynamic range and Multiexposure. Through the multiple scanning with different exposures, the effectice range of density of a scanner is increased.

If during the scan with the SilverFast Ai Studio or SE Plus the Multi-Exposure function is activated, the scan procedure takes approximately double as much time, but therefore one mainly saves the image processing afterwards that should be accomplished in order to get similar results. Anyway, despite of the image processing, the result does not fully meet the one of the MultiExposure scan, as it simply teases out more image information from the original than a single-exposure-Scan. This image information cannot be "conjured up" afterwards.

Conclusion: those who have a SilverFast-version with a Multi-Exposure function should make use of it, even though the scanning time is significantly longer. Multi-Exposure often provides some significant increases in the quality of the scans, even though they are not clearly visible in all motifs.

Which kind of quality increase does IT-8 calibration provide?

A key feature of SilverFast Ai Studio is the IT-8 calibration fors canning slides (positives) and reflective originals (photos, documents, paper, etc.) with fadeless colours. The scanner is measured with an optional Target and a color profile for the scanner is created. The information in this color profile can then be used for each scan, in order to perform a corresponding image correction. The importance of an IT-8 color calibration at film- and flatbed scanners is hard to imagine. The best way to show the increase of the quality by the IT-8 calibration is using examples. Click on one of the images and a new window will be opened, which changes between the presentation of the profiled and the non-profiled image.

The first two images were scanned with the very high quality and expensive professional film scanner Nikon Super CoolScan 5000 ED and SilverFast Ai Studio. An ICC profile was created, and we have digitized each images with and without consideration of the profile. You can see clearly that a professional device like the Nikon LS-5000 ED already delivers very good image results without calibration. By the IT-8 calibration, the colors are displayed correctly and faithfully, and it will save you the subsequent post-processing image editoring.

The adjacent two images were digitized with an affordable film scanner, which is popular under hobby photographers and semi-professional users Reflecta ProScan 7200. Here we have als ocreated an ICC profile with SilverFast Ai Studio and with the help of an IT-8 target and then we scanned the image once with and once without consideration of the profile. It can be clearly seen that the differences between the unprofiled and profiled scan are strong. While the non-profiled scans are strongly colored and image editing is necessary, the profiled scans are very useful.

It is noticable, that every picture which was scanned with the IT-8 color profile has more natural colors - like the motives in reality and on the film. We have done without manual corrections such as adjusting the tonal values with the scanning software to give you an objective impression of the quality improvement.

As you can see, the calibration brings even with high-end devices like the Nikon Super Coolscan 5000 ED an improvement of the image result. The differences are even larger using the inexpensive scanner Reflecta ProScan 7200. Generally speaking, the IT-8 color calibration yields even more when a cheaper scanner is used.

How the IT-8 calibration processes works, is explained on our site scanner calibration. More information about the IT-8 calibration you can find on this page unter IT-8 calibration.

What are the advantages of the NegaFix dialogue for scanning negatives?

SilverFast Ai Studio provides the IT-8 color calibration in a very effective method for scanning positives and paper images to create true-color scans, matching the colors of the original template. Unfortunately, the IT-8 calibration does not work with negatives because of the orange mask of negative films. But SilverFast has integrated also a powerful feature for image enhancement for negative film, namely the NegaFix dialogue.

The SilverFast NegaFix dialogue allows to directly set the used type of negative film. Then the corresponding color and contrast adjustments are made based on a specific profile for each film. The improvement in image quality when scanning negatives is substantial if one sets the correct film type within the NegaFix dialogue. This also applies to black and white negatives, because these types of films can be also selected.

The improvement in quality can be demonstrated best by example. We have scanned the negatives with the Reflecta ProScan 7200 once with the proprietary software Cyberview and once with SilverFast Ai Studio and the appropriate type of film selection in Negafix. Simply click on one of the pictures, and in the opening window the images alternate between the two scans presented.

The first picture shows a Kodak Farbwelt 200 film, the second one a Fuji Superia 200 negative film, and finally we have also a black and white negative film of the type Kodak T -Max 100. No manual corrections and additional filtering was made at the scanning program in order to make the difference visible clearly. In the comparisons we can clearly see that the scans with SilverFast Ai Studio correspond more to the reality than the scans with Cyberview. The colors are natural and glowing. The black and white image with SilverFast Ai Studio has much more contrast, as one expects for a T-Max film (with push processing).

In the NegaFix dialogue of SilverFast almost all known negative films are listed in the order of producers, but one or the other user maybe has a film, for which there is no specific color profile. In this case, you have to try by one of the existing profiles to find out which one is the best. The selected profile can then be adapted and saved with a different name. So you create your own color profile, which can be repeatedly called.

By the way the working method of the Negafix dialogue should not be mistaken with a scanner calibration. In the process of scanner calibration (only for positive and reflective originals) the color errors of the scanner are measured and stored in a correction profile. Within the NegaFix dialogue (for negatives) there is only a given color profile selected in order to optimize the corresponding film footage.

By the way, the NegaFix- function is not a special features of the Ai Studio version. Also the low-prized SE-version and the SE-Plus-version already have the NegaFix-dialogue integrated.

Where is the multiple scan function at SilverFast 8?

SilverFast Ai Studio 6.6 offered the possibility of a multiple scan, the so-called MultiSampling additionally to MultiExposure. Thereby, the original film can be scanned up to 16 times. Because the Scans with MultiExposure are much better than with a simple MultipleSampling SilverFast 8 offers only MultiExposure. If you still own a Version 6.6 of SilverFast you are able to use also MultiSampling. Based on the following examples, we want to show what a multiple scan provides in practice and how many times an original should be scanned in order to get some optimal results.

During the MultiSampling, as the name already says, the original is scanned several times. But contrary to the MultiExposure, the same exposure is always kept. These exactly equal single scans are then computed by the software to one single image, whereby the appearing sensor noises mainly appearing in the dark image areas are recognized by a comparison of these single images and removed.

The adjacent sample image has been scanned once, twice and eight times with a Reflecta DigitDia 5000. By clicking one of the thumbnails, an image window is opened with a 100% outcut of the red marked area that switches any 3 seconds between the single and the multiple scan.

What is noticeable is that the image noise is considerably reduced after the second scan. In the 8x scan, the image interference is further reduced, but the difference to the 2x scan is not so considerable anymore as it is between the first and the second scan. During the tests, the same image was also scanned 4x and 16x. Thereby, it became clear that the reduction of the noise indit increases with the increase of the scanning frequence, but the increase is lower from stage to stage. This means that the improvement of the image results from a 8x scan to a 16x scan is lower than the improvement between the 1x and the 2x scan.

We could see in our tests that the scan result is the better the more the original is scanned. While the increase of the quality between the 1x-scan and the 2x-scan is very considerable, by a further increase of the scans to 4x, 8x, and/or 16x it only slightly increases.

In case of multiple scans, the time factor plays a decisive role. A 2x scan takes almost double as much time as a normal scan. A 16x scan takes, depending on the scanner model, half an hour or even several hours of time. Thus, those who are not in a hurry during the scanning should make use of the multiple scan function. As the quality increases mainly have an effect on the dark image areas it is also a possibility to sort out the dark pictures of a collection and, separated from the bright ones, digitalize them with the multiple scan function.

IT-8 Colour Calibration

Which advantage does the IT-8 colour calibration offer?

As a screen without any expert calibration (see our page Screen Calibration) does not show the real colours, a filmscanner also does not provide any scans with 100% real colours. A red surface does appear after a scan as such, but it can occur that a scanner shows a red surface with the tonal value 200 (scale 0-255) only with the tonal value of 190, thus a little dark. By the respective calibration of the scanner, this difference is measured to the actual value and in the net scan, a correction is performed automatically.

Beside this imperfection, there are differences from scanner to scanner, even if the model is the same. By scanning an image with ten different scanners of the same production line, one gets 10 different scans that slightly differ in the colours. Also, if one scans an image ten times with the same scanner at different days, one gets ten different scans, as a scanner slightly changes its features depending on external influences as temperature.

With an IT-8 calibration, such effects can be compensated. Therefore, a so-called IT8 calibration target is needed; thereby, it is about a standarised template with numerous individual colour fields. This standard image is scanned and the calibration software measures the scanned colours in each of the colour fields. After that, the software compares the measured colors with an IT-8 reference table that contains the actual RGB values for each of the color fields. From this comparison, a table of differences that contains the colour deviations of the scanner results. From these profiles, the SilverFast software generates an ICC profile. In future scans, the scanned colors are corrected by this ICC profile so that one gets some scans with real color values.

The biggest advantage of an IT-8 calibration is then noticeable in the image processing after the scanning: the colors are real and natural, there is practically no colour correction needed in the image processing programe. A function as the auto-correction of the tonal value in Photoshop® does practically have no effect any more. Thus, by the IT8 calibration, one corrects the colour impefections of the scanner at the root and does not have to correct the scanner imperfections in the image processing afterwards in thousands of image files one by one. You will find some detailed information about the scanner calibration in our own page under the topic Scanner-Calibration.

How is the IT-8 color calibration accomplished in practice?

For filmscanners you normally use a framed 35mm IT-8 Target. This has to be handled like a normal slides and a preview scan has to be done. In this preview, the 22 x 12 colour fields are recognizable as also 24 grey fields thereunder from black up to white. By pushing the It-8 button in the SilverFast software, the calibration procedure is started where SilverFast shows a scan frame with a lot of small fields that has to be exactly adapted to the preview mask. This procedure is supported by an explaining dialogue.

As soon as the mask is positioned rightly and has the right size, the color calibration is started per mouse click. After one minute SilverFast has scanned the IT-8 target and compared the scanned colours with the referred table. The differences are filed afterwards by SilverFast in an ICC-profile archive.

In the following scans, SilverFast uses the individually created profile automatically and embeds it in the image files. By this way, one gets scans with corrected and optimized colours that almost do not need any further processing. This is best recognizable by opening such a file in Photoshop®. Photoshop® recognizes the embeded profile and employs it. By observing the tonal value curve, it covers almost the complete area of 255 values, as if an automatic correction of the tonal value has been made.

In case of flat bed scanners, the IT8 target is not provided as film but as a non transparent unit that is layed on the glass surface of the scanner as it is done with a normal paper image. Here, also a preview is done, the scan area for the IT-8 calibration is determined and SilverFast accomplishes the calibration automatically.

How often should the IT-8 calibration be accomplished in a scanner?

A scanner only provides good and real colour values if it is calibrated with the support of an IT-8 calibration target. But how often has such an IT calibration to be accomplished, is it a procedure that has to accomplished once or repeatedely?

All scanners have a certain radical error that is a certain grade of deviation in terms of colour that is construction-conditioned and that is within certain range of tolerance of the model range. This radical error is compensated by a unique IT-8 color calibration. But the features of the scanner change in the course of its life. As it is the case in a screen where the colours wash out or bleach a little in the course of the years, the colour representation of a filmscanner decreases in the course of the months and years. In order to compensate this creeping error, one should accomplish the IT-8 calibration once a month.

Those who attach highest importance to an absolutely real colour rendering in the scanning should accomplish an IT8 color calibration every day before a scanning session, as the quality of a scanner also depends on the day fluctuations. The CCD-sensor for example measures different values in a room of 40°C than in a room of 20°C surrounding temperature. Thus, the professional users who attach highest value to the color fidelity do calibrate their scanner every day. As this only consumes a few minutes of time, it is feasible without any problem.

Where are the reference files for IT-8 targets of SilverFast available?

On the IT-8 calibration target of the company LaserSoft Imaging, a bar code is contained with which the calibration software recognizes which reference file belongs to the target. This reference file is saved on the respective file and if not, the software searches automatically for a matching reference file on the website of SilverFast. Those who want to supply the reference files by themselves can do this on the website of SilverFast IT8 Reference Files.

Problem: SilverFast cannot find any Reference Data File

Those who buy the SilverFast Ai software mostly also buy an IT8 calibration target. The respective reference file is available in the CD of SilverFast. In case SilverFast does not find the right file, the software will search for it in the homepage of SilverFast.

But it happens to some users that SilverFast does not find any reference file at all. What is the reason for this? Many users do set the IT-8 calibration slide mirror-inverted by mistake into the scanner. Then the software cannot recognize the barcode and/or identifies it wrongly and asks for a reference file that is not existent anywhere. In this simple case, the problem is simply solved by turning the IT-8 target and restart scanning.

For the case SilverFast does indit not find a matching reference file neither on CD nor through an internet connection, there is still the possibility to download the reference file by oneself from the website of SilverFast, in this relation you can have a look to our respective chapter. Of course, LaserSoft Imaging only provides reference targets for the own targets. Those who obtain a target from a different resource must also obtain the reference file from the respective producer.

Which IT-8 target should be applied, Kodak or Fuji?

LaserSoft Imaging provides SilverFast Ai filmscanners by standard without targets. What is additionally available and/or by paying an extra charge is a Kodak or a Fuji IT-8 target, therefore please look for example to the commodity group IT-8 Targets in our filmscanner shops.

Which target does provide now the better scan results? For example, a scanner as the Reflecta DigitDia 6000 with a colour fidelity of 80% (whatever a percentage of colour fidelity might mean). With the help of the IT-8 calibration, the colour fidelity is increased from 80% to 95%, this means that one gets almost perfect colours the way they are contained in the original. This increase is either achievable with the Kodak IT-8 Target as also with the Fuji IT8-target, no matter if one digitalizes Kodak-films, Fuji-films, Agfa-films or other films.

Every semiprofessional photographer knows that as every film producer, every type of film has its specific features concerning colour and grain. The evaluation if a film is better or worse is partly only possible on a subjective basis. Some photographers only made photographies with Fuji-films for a lifetime, some exclusively used the ektachrome-films of Kodak. Of course, one only gets all the colour fidelity from the scanner by choosing the target according to he film material to be scanned. In the case of the Fuji-velvia films, a Fuji-IT-8 target for the calibration of a scanner provides nearly 100%colour fidelity, a Kodak-IT-8 target provides in case of Kodak-ektrachrome also nearly 100% colour fidelity. In case of a combination, one gets the 95% of colour fidelity mentioned above. For the Agfa-films, we also recommend the Fuji-target, as it is closer to the original colours of the Agfa-films.

Are there IT-8 targets for Kodachrome-films available?

The scanning of kodachrome-films is a difficult matter. With normal colour profiles, one gets some blue cast scans and the ICE dust and scratches remover based on the hardware leads in the case of most of the films to some unacceptable loses of the details. The question if there are some IT-8 targets for Kodachrome-films available had to be answered up to the turn of the year with a NO, as until then, there was no producer who offered the respective targets in their range.

Finally, at the beginning of the year 2009, LaserSoft Imaging introduced a Kodachrome IT8-target into the market at a reasonable price, so that an IT-8 colour calibration can be accomplished specially for the Kodachrome-films. As described in the following text under the title Profile administration , within the SilverFast scnsoftware, it is possible to create different IT-8 profiles and choose them by a simple mouse click.

Since March 2012 we also offer a Kodachrome-Target produced by Kodak. It is a bit cheaper than the LasersoftImaging one but you need a third supplier software to calibrate the scanner. We offer further informations about Kodachrome slides on our KnowHow site Scanning Kodachrome Films.

How is it possible to recognize the type of film of an IT-8 target?

There are different film types and sizes of LaserSoft Imaging for the IT-8 Targets. While the size can be simply measured or estimated, the type of film is only recognizable by thorough observation of the target.

On a LaserSoft Imaging IT-8 target in a framed slide (35-mm film), the type of film is readable on a vertical text line at the right edge of the target, for example as in the adjacent picture "Printed on Kodak Ektachrome Professional Film". The text is hardly decipherable to the pure eye; but by observing the slides with a magnifier or after a high resolution scan, the vertical text is easy to read. In case of a non-transparent target of LaserSoft Imaging, the type of film at the right bottom are clearly readable, as you can see in the example of the second image the text "Printed on Kodak Professional Digital". These images are zoomed cutouts of a scan of the respective IT-8 target.

How long does an IT-8 target keep its original quality?

An IT-8 calibration target is a high quality piece of film material in the field of transparencies that contains certain standard colors on a certain film (for example Kodak or Fuji). Like at all other photographic films, an IT-8 target also ages and loses its color fidelity. How long is it possible to use an IT-8 Target?

Those who keep their photographic films in a cold, dry and dark place can still enjoy also after 10-20 years best colors like the way they were right after the development of the film. Of course, the same also applies for an IT-8 target if it is kept in a cool, dry and dark place. Due to this reason, a target should never be simply left on the desk or on the scanner. If it is exposed to the sun or to heat as for example from the screen, it will ages quickly and will lose its reference colors. The result is a defective scanner calibration; the respective defective colors are transferred to each of the scanned images.

An IT-8 target should be kept in a cold, dry and dark place.

How are the profiles of different IT-8 targets handled?

If one wants to create some own ICC profiles for different types of film, the respective target must not be scanned each time. Instead, an own profile can be create for each target and it can be activated when itīs needed. The procedure for this is as follows:

First, the function Own ICC-Profile Name must be activated in the Auto-Tab of the option dialogue

By clicking on the calibration button, one can create a name for it after the completion. Thereby, one can also include the date and the type of film in the file name.

Now, by opening the CMS-tab of the option dialogue (see adjacent image), one can see that the just created profile has been selected as the input profile. If one wants to create another profile with a target of a different type of film, the calibration procedure has to be repeated with the new target. Then, one assigns the respective name to the new profile. This profile is now automatically selected as the input profile.

In the CMS-Tab of the option-dialogue, one can now switch between the different profiles and thereby choose the matching one to the respective film material. This procedure can be repeated as many times as wanted, so that an unlimited number of different input profiles can be created.

Why does the IT-8 calibration not provide a noticeable quality increase?

From time to time, some of our clients complain that the IT-8 colour calibration does not provide a significant increase of quality in the scans. Also in our forum, the owners of the same scanner model discuss whether the calibration and profiling of the scanner does make sense or not. In one case, the IT8-calibration really made wonders, in the other case, the owner of the scanner barely notices any difference. How are such different statements possible? Is the quality increase only a subjective perception of can an objective statement be given about that?

Every technical device is subject to certain quality fluctuations and works in a firmly defined area of tolerance. Example: in the case of a scales, the producer indicates that, for example, it measures a weight of 100 kg with a tolerance of +- 2 kg. If now 3 persons buy a model of this scales and weigh a block of 100kg, the first will for example get a weight of 98kg, the second maybe 102 kg and the third possibly exactly 100 kg. If those 3 buyers let their scales to be calibrated (gauging)at the board of weights and measures, then, after the gauging, all 3 buyers will get a uniform weight of 100 kg by weighing the block. The first and the third buyer will say that the fee of 50 € for gauging fully was the money worth; but the second will say that the gauging did not make much sense as it only cost money. By this way, every buyer evaluates individually the sense and benefit of a gauging with costs at the board of weights and measures. But after the calibration, all 3 of them have the guarantee that their scales works in the right way.

What I mentioned in the above example also applies for a scanner: every filscanner works within a certain area of tolerance; in case of one modell the colours strongly differ from the natural colours, the other model's colours correspond very well to the original ones. An IT-8 colour calibration effects that the scanner is set to a clearly defined quality level, no matter if the level was high or low before the calibration. Thus, after the colour calibration one can be sure that the scanner provides real and natural colours.

Conclusion: the IT-8 profiling provides a high quality level to the scanner concerning the colours and the colour fidelity. But the actual need of correction differs from scanner to scanner and changes in the course of the time.

In order to come back to the initial questions: thus, a user complaining that the IT-8 calibration did not change much got a good device from the production by which not much corrections were necessary. But as a scanner changes its features in the course of its lifetime, the calibration may not show some effective results until a period of 3 months. And the different users who report in a forum of the sense and benefit of the IT8-calibration of their device are, of course, all right concerning the results in exactly one scanner. In one case, a large correction was needed, in the other case only a small one. But the results of a subjective evaluation do not apply generally on a type of device. For this, a statistic of umpteen or even hundreds of subjective evaluations were necessary.

IT-8 calibration with advanced IT-8 Targets

In the year 2018 Lasersoft Imaging brought a new target series on to the market. The so-called advanced targets are based on the new standard ISO 12641 part 2.

What are advanced IT-8 targets?

When in the year 1993 the IT-8 standard was published in the ISO 12641 the structure of transparency targets (IT8.7/1) and reflective targets (IT8.7/2) was defined. According to this standard in the years 1993 up to 2018 transparency scanners and reflective scanners were calibrated with suitable targets. This "old" standard continues to apply in the ISO 12641 as part 1, also noted as ISO 12641-1.

It took time until the year 2018, when finally a nes standard for the IT-8 colour calibration was defined in the ISO 12641-2. This new standard, also denoted as ISO 12641 Part 2, is based on new targets, which are designated by advanced targets.

The "old" targets according to 12641-1 consisted of 22x12 colour fields, i.e. 264 colour fields in total, as well as a grey scale with 24 fields; so in total 288 measurement fields. The advanced targets according to ISO 12641-2 consist of 864 colour fields. Thus at the scanner calibration more colour fields are measured and compared with reference values, so that less colour values have to be interpolated and an exacter calibration is possible.

Advanced IT-8 targets are available both for scanners with transparency unit (IT8.7/1) and for scanners for reflective originals (IT8.7/2). On the reflective targets and the larger transparent targets the 864 colour fields are arranged in 36 coloums and 24 lines. On the 35mm transparency target the film area with 36x24mm is too small for 864 colour fields, so that these colour patches are split on 3 targets.

Furthermore on all advanced targets there is a bar code with which SilverFast can automatically find the nomber of the appropriate reference file. This feature is well-known from the "old" target series. At the bottom of the left side of the target there is the manufacturing date.

Which film types are available at the advanced targets?

There are both advanced transparency targets (standard IT8.7/1) and advanced reflective targets (standard IT8.7/2). The transparency targets in the sizes 35mm, medium format 6x7 mm and large format 4x5" are made on Fuji Provia 100F film. The reflective targets in the sizes 10x15cm, 13x18cm (5x7") as well as full format targets in the size 15x22cm are made with Kodak Professional Endura paper.

At the "old" target series according to ISO 12641-1 there were different film types both for transparent targets and reflective targets. In the transparency area one could choose between Kodak, Fuji and Kodachrome films, in the reflective area one could choose between Kodak and Fuji. This selection possibility is not given any more for advanced targets according to ISO 12641-2. Thus a film typical calibration is not possible any more. And this will not change in the future, since Kodak films and Kodachrome films are not be produced any more.

What are the advantages of the advanced IT-8 targets compared to the old IT-8 targets?

The "old" IT-8 targets according to the standard ISO 12641 Part 1 had 288 measurement fields. During the calibration process all these measurement fields were measured and compared with reference values. For colour tones which were between these measurement fields an interpolation had to be done. The advanced IT-8 targets according to the standard ISO 12641 Part 2 have 864 measurement fields so that less interpolations have to be done. Furthermore these new IT-8 targets have additional colour fields with dark colours and pastel colours. It is clear that a more precise measurement and a more exact colour calibration is possible with more measurement fields.

However in practice this more precise exactment of measurements cannot be proven. We have calibrated several scanners with the old part 1 targets and the new part 2 targets and compared the resulting scans. Indeed we could not recognize any improvements of the image quality by using the advanced targets. Probably the differences and improvements only can be recognizes by precise measurement instruments.

Let's have a look at the adjacent picture. If you click on the image a new window opens with an animation of 3 images. First you will se a scan, which is produced by a reflecta ProScan 10T without scanner calibration. In the second animation picture you will see the scan of the same reflecta ProScan 10T after calibration with a standard target. Finally in the third picture you will se a scan of the same ProScan 10T calibrated with an advanced target. At this animation you can clearly see that the calibration leads to an essential increase of the image quality at this film scanner. However, you hardly can recognize any differences between the scans with the different calibration targets.

In practice one does not achieve image quality improvements by using the advanced targets instead of the old IT-8 targets for the scanner calibration.

What are the disadvantages of the advanced IT-8 targets compared to the old IT-8 targets?

As described in the chapter Film types of advanced targets advanced transparency targets are only available on Fuji film and advanced reflective targets are only available on Kodak paper. At the old part-1 target series one could choose between different film types. If you want to digitize a bunche of Fuji-films you can make a perfect colour calibration with an advanced Fuji IT-8 target. However, if you intend to scan a series of Kodak slides you will not find a suitable part 2 target. Also if you plan to scan Kodachrome films there is no suitable IT-8 target in the advanced target series.

Of course you can calibrate your scanner with a Fuji film target and scan Kodak films. However, a Fuji IT-8 target includes the characteristic film properties of a Fuji film and does not reflect the film properties of other films. If you intend to digitize Kodak films or Kodachrome slides you better use old IT-8 targets as long as Kodak targets and Kodachrome targets are still available. In the reflective area the film type is not decisive.

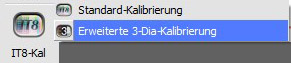

Which SilverFast version is neccessary in order to user advanced IT-8 targets?

The Die Advanced Color Calibration Targets for a scanner calibration is available starting with the version 8.8.0r11 in SilverFast Ai Studio or in the SilverFast Archive Suite. Older SilverFast versions only can handle "old" IT-8 targets according to ISO 12641 Part 1 and create a colour profile.

Where das SilverFast Ai know from if a standard target or an advanced target is used for calibration?

Since the version 8.8.0r11 SilverFast Ai Studio can do an IT-8 colour calibration with advanced targets according to the standard ISO 12641 Part 2. A colour calibration with standard targets according to ISO 12641 Part 1 is possibly anyway. If you click on the IT-8 calibration button since the version 8.8.0r11 a selection field opens for choosing the standard calibration with old targets according to ISO 12641 Part 1 or the advanced calibration with advanced targets according to ISO 12641 Part 2. In the 35mm area the advanced calibration is denoted with Advanced 3-slide calibration, since the 864 measurement fields are split on three 35mm targets and so 3 IT-8 targets have to be scanned.

Why is indicated after the calibration that less colour fields have been used?

The Advanced Color Calibration Targets have 864 measurement fields in total. In practice not always all these colour fields can be used for the measurement. For examplare due to dust on the target or inside the scanner it might happen that some colour fields have to be omitted during the calibration process in order not to produce wrong colour values for the resulting profile. However doing without some colour fields still enables an exacter colour calibration than using faulty measurement values to to dust.

An additional factor for the nomber of used measurement fields is the colour space. It might happen that some singular measured colour tones are outside of the used working colour space. In this case these measurement fields will not be considered for the resulting ICC profile. Even if some colour fields are not used there are much more than 800 measuremtn fields left for creating an exact ICC profile.

What is the Delta E value?

When the IT-8 calibration is done successfully the Delta E value us shown. The Delta E value gives the medium aberration, i.e. the average aberration of the measured values from the expected values of the reference file. In most cases the Delta-E value lies between 0,8 and 1,8. However, if a value of 3.0 is given, this can be considered as normal. The ICC profile includes the deviation from the reference file so that the colours of the original will be displayed correctly.

Dust and Scratches Corrector SRD, iSRD, ICE

Is the dust and scratches remover SRD of SilverFast equal to ICE?

The most renowed is the corrector of dust and scratches based on the hardware Digital ICE. SilverFast offers a dust and scratches corrector named SRD that is based on the software. How does this procedure come off compared to the ICE? Can it be used in the batch modus?

First, the essential difference between both proceedings should be mentioned: ICE is a proceeding based on the hardware; with an infrared light resource, the original is scanned for detecting eventual irregularities so that dust grains and scratches are detected. This error spots can be then corrected afterwards by the software. Thus, the Digital ICE works by pushing a button, which means there is a status of switched on and off. Due to the additionally necessary infrared light resource, it can be only applied in those scanners that are already structured for ICE, in this concern you can also see our page Correcting Procedure.

SRD of SilverFast is a purely software algorithm. Those image spots where the dust and scratches have to be applied are to be selected and a degree of strength must be adjusted. After that, a sophisticated algorithm of computation is started that recognizes the spots on the image and retouches them. Thus, while the ICE recognizes the dust particles on the basis of the hardware, the SRD is based on an image recognition algorithm that of course cannot distinguish if a small spot is a bird or a dust grain. But ICE can recognize this difference, as a bird corresponds to some image spots, but a dust grain forms a slight raise on the film material.

Thus, ICE can be switched on per mouse click while SRD must be laboriously individully applied on each image area. The selection of all spots on the image where SRD should be applied can easily take half an hour. Timewise, there is no difference between both functions, as ICE more than doubles the scanning time and SRD needs a lot of computation time in the image processing. Thus, the main difference is that ICE runs fully automatically and that it is based on the hardware, while SRD must be manually applied for each image individually, that is, for each image there is an additional work of up to half an hour. ICE can be simply switched to the batch modus, while SRD does not automatically remove the dust spots in each image in the batch modus.

ICE is a correcting function based on the hardware that is activated by pushing a button. SRD is an effective algorithm for the image processing, but it requires a time consuming selection of the spots to be processed for each image.

SDR is without doubt an excellent image processing function. But it does not reach the performance, effectiveness and easy handling of the ICE dust and scratches corrector.

What is the difference between SRD and iSRD? The dust removal?

SilverFast supports different methods of the dust and scratches removal in different versions depending on the device. The simple method is called SRD, the better method is called iSRD. Where is the difference? To make it short, SRD is based on the software while iSRD runs based on the hardware and the software.

SRD is a pure software function that must be manually controlled: on the preview image, one selects the dust grains individually and the software corrects these dark spots based in the image information around them. SRD does not work automatically for a complete image but only for individual spots that are manually entered. As one has to make the selection manually for each image, SRD is an extremely time consuming matter and not suitable at all for mass scannings.

iSRD is a dust and scratch removal function that is additionally based on the software by using the infrared channel of the scanner for the detection of dust grains and scratches. Thus, iSRD works exactly like the funtion ICE (see our page about Correction Procedure). Contrary to SRD, iSRD works automatically; thus one does not have to select dust grains individually but simply switches on the function and leaves the detection of dust grains and scratches on the image to the infrared ray of the scanner. iSRD works very reliable nd increases the image quality significantly. Due to the procedure, the scanning speed is reduced by half but no personal working time is required.

At SilverFast 8 there are some new features for example for scanning Kodachrome-Slides. You can choose between four differnet kinds of displaying the defects: Mark, Correct, Automatic and Original. You can use these Features to controll the Dust and Scratch Removal easily at the preview. With the modulation "Detection" you can influence the degree of efficiency of the Dust and Scratch Removal. This is particularly useful for Kodachrome-Slides because of the oftentimes appearing problem with the Dust and Scratch Removal. This modulation helps to reduce the problem of lost picture details. The Studio Version also offers to use iSRD with layers and masks within the expert dialog. And the opportunity to influence the detected size of the defects. These features are especially for superior Scanoperator and professionals.

Is there any difference between the dust and scratch correction procedure ICE and iSRD?

On our website about different Correction Procedures, the automatic dust and scratches remover ICE is described in detail. It is about a very reliable method that was already developed in the beginning of the millenium and that has been implemented into many scanners. In some scanners, there is no ICE but iSRD in the SilverFast-software, although the scanners are actually delivered with ICE. Where is the difference?

Both procedures are based on the hardware; they use the infrared ray of the scanner in order to detect the mountains and valleys on a slide or a negative. Thereby, the mountains correspond to dust grains and valleys to scratches. Once the dust grains and scratches are detected, the intelligent algorithms can correct those spots on the image based on the image information around them. This is why it is called automatic dust and scratches removal.